Introduction

This guide details a partial disassembly of the shutter mechanism. After disassembly, the user should be able to diagnose and fix most jams and other malfunctions.

Following the guide will also give the user access to most of the critical lubrication points for for routine maintenance. This can keep a healthy shutter running well. If the shutter has major problems and the timing is far out of spec, the components may be dirty and require further disassembly and cleaning before lubrication.

The photos in this guide show the camera with the advance mechanism already disassembled. It is not necessary to do this first but is sometimes necessary to make changes to the transport gears.

Tools

-

-

Loosen three grub screws. Do not remove them from the frame counter cover.

-

Lift off frame counter cover.

-

Remove one 2.5 mm flat head screw. It is reverse or left-hand threaded.

-

Remove the frame counter dial.

-

Remove the retaining nut using a spanner wrench. A pair of fine tipped nippers can also work.

-

Remove the dial seat.

-

-

-

Remove three 2.3 mm flat head screws.

-

Use a pick to rotate the retaining washer until the lobed sections are free.

-

Lift off the advance lever.

-

Remove the plastic shim washer.

-

-

-

Remove one 2.8 mm pin head screw.

-

Remove the shutter speed dial.

-

Remove the ISO dial.

-

Remove the internal spring.

-

Remove the dial housing.

-

-

-

The hole in the dial housing needs to go over the tab on the speed resistor.

-

The tab on the ISO dial needs to mate with the hole in the dial housing.

-

It can be difficult to line everything up while compressing the spring and installing the center screw. Be patient.

-

-

-

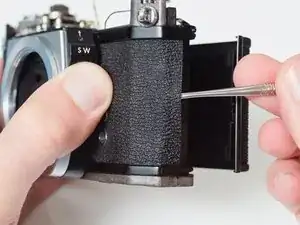

Place a thin, sturdy tool in the spindle fork.

-

Unscrew the rewind knob.

-

Use a spanner wrench to unscrew the retaining nut.

-

Remove the film reminder

-

Remove the spring washer.

-

Remove the friction plate.

-

-

-

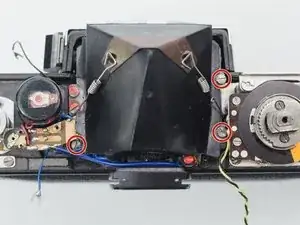

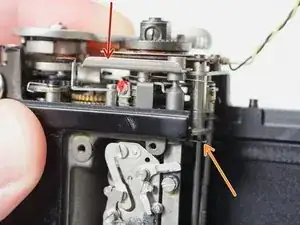

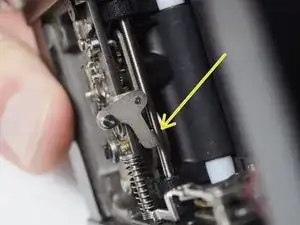

This is an example of a properly functioning mirror charging mechanism.

-

The large gear on the far left is driven by the film advance lever on top of the camera.

-

The long silver lever is the mirror charging lever. It pushes the black bar to the top of the slot when the camera is wound, which charges the main mirror spring.

-

The lever on the right holds the black bar in place while the camera is cocked and ready to shoot.

-

At the end of an exposure, the large black gear pushes the release lever, returning the mirror to the viewing position.

-

-

-

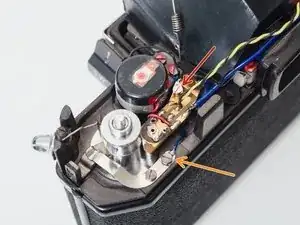

Unscrew or unsolder one black wire. This is the main power coming from the meter switch on the side of the mirror box.

-

Unscrew one blue wire. This is the ground wire that connects the meter circuit to the body of the camera.

-

Unsolder one yellow and one black wire from the speed resistor.

-

-

-

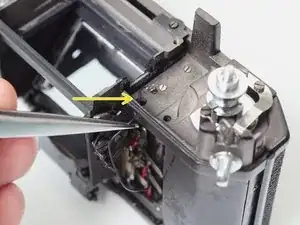

Remove cover screw using a spanner wrench.

-

Remove the self timer lever. The internal mechanism will unwind past the installed position when the lever is removed.

-

-

-

Apply isopropyl alcohol to the edge of the leatherette covering to soften the adhesive.

-

Use a dull scraper to get under the edge of the leatherette and begin peeling it off.

-

Fully remove the leatherette covering from both sides of the camera.

-

If the self timer lever can't be removed, the leatherette can be peeled away just enough to access the screws.

-

-

-

Remove four 4.6 mm flat head screws.

-

Remove one 4.3 mm flat head screws.

-

Lift off front lens board.

-

Note the position and number of shim washers at each screw location. They need to be installed in the same positions during reassembly.

-

-

-

Unhook mirror return spring.

-

Unscrew one 4.8 mm flat head shoulder screw.

-

Remove keyed washer.

-

-

-

Unsolder two red wires. These connect to the X-sync contact.

-

Unsolder one black wire. This connects to the battery compartment contact.

-

Pull black meter wire through the whole in the chassis.

-

-

-

Remove one 4.3 mm flat head screw.

-

Remove one 4.5 mm flat head shoulder screw.

-

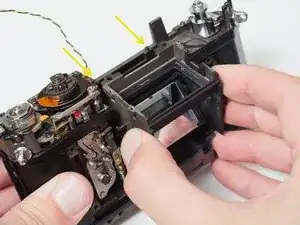

Lift mirror box up and over posts on the back of the camera. The posts can be removed for easier removal and installation if necessary.

-

-

-

The shutter should be released before installing the mirror box.

-

The mirror charging lever needs to be behind the mirror actuator lever coming from the mirror box.

-

The post from the shutter release shaft should be above the mirror release lever on the mirror box.

-

-

-

With the mirror box removed, the shutter can be fired by pushing the shutter release bar...

-

and releasing the opening curtain latch

-

-

-

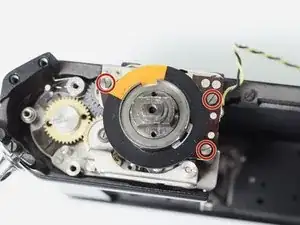

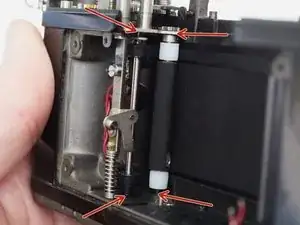

Remove two 3.0 mm flat head screws.

-

Remove one 5.0 mm flat head post.

-

Remove the speed selector assembly.

-

The high speed cam may stay in the selector assembly when it is lifted off. Fully remove it for cleaning and lubrication.

-

There is a small bushing on the opening curtain wind gear. Remove it so that it doesn't fall off unexpectedly.

-

-

-

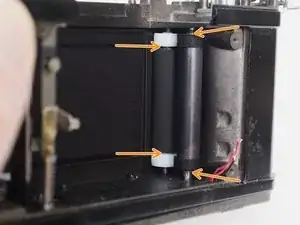

Lift out the delay rod.

-

Lift out the pallet rod. Note the small bushing on the end so it doesn't get lost.

-

-

-

Check that the pallet and delay rods are properly coupled with the slow speed governor (if installed) and seated in their pivot holes.

-

Check that the upper levers of the rods are in the correct positions around the wind gears.

-

Place the high speed cam on top of the wind gear. Make sure the driving peg rides in the slot of the cam.

-

-

-

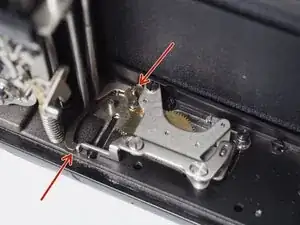

Wind the shutter.

-

Remove one flat head threaded post.

-

Remove transport plate.

-

Remove transport latch.

-

Remove upper transport gear.

-

Remove lower transport gear.

-

-

-

Clean the transport gears and the mounting post with isopropyl alcohol. Do not lubricate.

-

There is a detent on the bottom of the lower transport gear that is held by a latch when the shutter is cocked.

-

Pull the latch out and push the lower transport gear all the way down so it can properly catch the detent.

-

Install the upper transport gear such that the gap on the right side of the latch is as small as possible without touching.

-

-

-

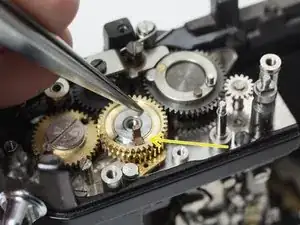

Lubricate the pinion shafts. On the wind side, the pinions turn in their end pivots. The oil should be between the shafts and the end plates.

-

Lubricate the rollers. On the rewind side, the rollers turn on the fixed shafts. The oil should be between the rollers and the shafts.

-

Lubricate the high speed cam seat. The high speed cam spins rapidly in this hole during an exposure. It should be cleaned and lubricated.

-

At this point, a basic shutter service can be performed. Important parts can be cleaned and critical points can be lubricated. If the shutter was performing normally before disassembly, this is good preventative maintenance and will keep the camera running smoothly. If the shutter is running poorly, with curtain times far out of spec, more disassembly and cleaning is recommended.

To reassemble your device, follow these instructions in reverse order.