Introduction

This guide will walk you through the steps of replacing seals on a Fox mountain bike fork (often called an "uppers service"). These steps can be applied to any modern Fox fork, though this guide focusses on a 2012 Fox 32 factory fork. Be sure to check the Fox website for the correct parts, fluid, and fluid volumes to use no matter what fork you are using (this will be done using the serial number on the fork).

Tools

Parts

-

-

Begin to remove the front brake caliper. Find the appropriate sized Allen key from your set, and remove the bolt by turning it counter clockwise.

-

-

-

Insert the caliper pad spacer to ensure the pistons cannot move while the caliper is off the fork.

-

-

-

Find the correct Allen key to remove the brake line bracket from the fork.

-

Remove by turning the bolt counter clockwise.

-

After the brake line is removed from the bracket, screw the bracket back onto the fork.

-

-

-

Find the proper sized Allen key to loosen the stem clamp bolts.

-

Loosen each stem bolt at least 3 turns by turning counter clock wise.

-

-

-

Find the appropriate sized Allen key to fit the stem bolt.

-

Remove the stem cap by turning the bolt counter clockwise.

-

-

-

Remove the cap on the left side of the fork by turning counter clockwise, exposing an air valve.

-

-

-

Use a small allen key (2.5mm was used in this case) to release all of the air from the fork.

-

-

-

On a work surface, flip the fork upside down and locate the red rebound knob.

-

Locate the small allen bolt and find the appropriate sized allen key. Loosen the bolt by turning counter clockwise 3 rotations and remove the rebound knob.

-

-

-

Find the appropriate sized hex socket to fit the nut that is under the rebound knob. Remove by turning counter clockwise.

-

-

-

Find a small socket that will rest on the shoulder below the threads but not damage the threads on the rebound side of the fork.

-

Use a soft headed mallet to lightly tap on the socket.

-

-

-

Screw the nut part way onto the threads on the other side.

-

Use a soft headed mallet and lightly tap on the nut.

-

Remove the nut and socket from the threaded parts of the fork.

-

-

-

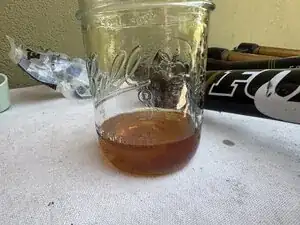

Get a large container to capture the oil inside the fork.

-

Flip the fork over above the large container, keeping in mind that oil will begin to flow out once the fork is turned right side up.

-

Hold the fork above this container and slide the stanchions out of the fork body.

-

-

-

Rest the new dust seal over where the old one was removed.

-

Use a socket the same diameter of the dust seal and a mallet to seat the dust seals.

-

-

-

Using the serial number on your fork, determine from the manufacturer website how much oil should be added to each side of the fork.

-

Dump the measured quantity of oil into a plastic bag. Close the bag, invert, and cut a small part of a corner off.

-

-

-

At this point, the fork can be turned right side up.

-

Unscrew the cap covering the air input (opposite side from the damper).

-

-

-

Grease the headset component in the bottom of the head tube, and the base of the steer tube.

-

To reassemble your device, follow these instructions in reverse order.