Introduction

This teardown was completed as part of my elective for advanced engineering at RMIT. This teardown took around 7 hours as I wished to avoid destructive methods of disassembly other than when necessary. To complete this you will need, Phillips head screw drivers, wed head screwdrivers, a drill and 3mm diameter bit, a centre punch, and the usual PPE.

-

-

Midea FC307B Rice Cooker (prior to this teardown) in full working order, though the outlet cable had been lost.

-

Cooker weighs 3.2kg

-

Length: 304mm

-

Height: 218mm

-

Width 210mm

-

-

-

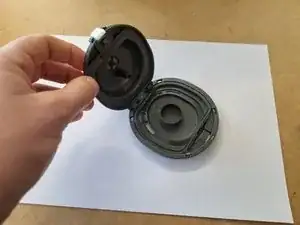

Top filter pops off easily.

-

Top weighs 65g (both parts)

-

Length: 117mm

-

Width: 90mm

-

Height/Depth: 35mm

-

Top filter further breaks down into two more assemblies held together with a hook hinge and a latch

-

-

-

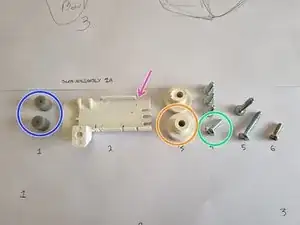

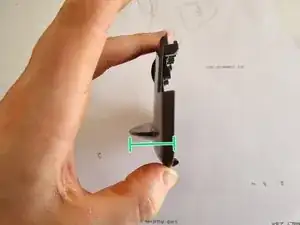

Latch mechanism is held to the part with a single Phillips head m2 screw

-

The 4 parts sit together (as shown) to form the latch mechanism.

-

Note: the large slot in the white button component, that allows it to slide past the screw which intersects it. The red line illustrated how the screw intersects it.

-

All component's are made from ABS plastic with exception of the stainless-steel screw, and steel spring.

-

-

-

The top of the filter had three parts that came off relatively easily. A neoprene gasket that could just be pulled off, the main injection moulded ABS plastic body. And a stamped stainless steel element.

-

The stainless-steel element had tabs that were folded around the main plastic body. It could easily be removed using a flat wedge screwdriver to flip them up.

-

These tabs folded into gaps on the underside of the plastic body.

-

Length: 117mm

-

Width: 90mm

-

Height/Depth: 12mm

-

-

-

Bottom component made from grey ABS injection moulded plastic.

-

Bottom is held to the upper body of the cooker using 4 long Phillips head m3 screws which had to be accessed with a long screwdriver.

-

Bottom was further supported by 2 shorter m3 screws that also held neoprene stoppers on the underside of the cooker. I am not sure what is the purpose of these neoprene stoppers, possibly heat insulation?

-

Length: 317mm

-

Width: 245mm

-

Depth/Height: 75mm

-

-

-

All the components I removed whilst unscrewing the bottom

-

White injection moulded ABS plastic housing for the outlet cable.

-

Neoprene white stoppers, held on using m3 screws. Not sure what purpose they have.

-

Neoprene feet, prevent the cooker from falling off a surface by creating friction with the surface.

-

13mm long m3 Philips head screws, holds the bottom of the rice cooker to the upper

-

-

-

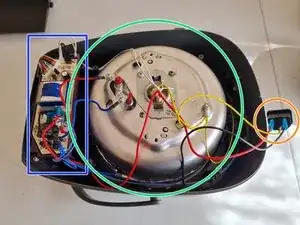

Removing the base by removing the screws, the inner workings of the cooker are exposed.

-

PCB circuit board - controls the cooker

-

Power outlet

-

Cooking/heating bowl - heats the removable aluminium bowl (second picture)

-

SEE STEP 18 FOR BOWL DETAILS

-

-

-

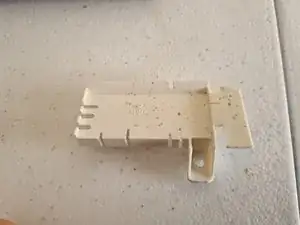

Mechanical buttons and circuit board are connected to a purple ABS injection moulded plastic frame

-

Frame is held to the main body of the cooker using 3 hard to access m2 Phillips head screws (here I have removed them)

-

Special hooks on the plastic frame for collecting and holding all the wires

-

-

-

Back cover had two purposes: (1) to prevent the handle from being able to line up with its slots (see next step) and (2) to cover the torsion springs that actuate the lid

-

Width: 32mm

-

Height: 77mm

-

Length: 130mm

-

-

-

After removing the bottom was able to see inside and see where the handle poked through onto the inside of the corner. Noticed the end of the handle had a nodule. Realised that the only way to remove the handle was to line up the nodule slot in the side.

-

Nodule slot on the handle, and on the side of the cooker

-

Weight of handle: 81g

-

Handle made from injection moulded ABS plastic. The mould notable has two halves indicated by the seam that runs along the inside of the handle

-

Height: 188mm

-

Width: 22mm

-

Length: 245mm

-

To remove handle and line it up with eh slots, the back cover had to be removed (previous step)

-

-

-

Removing the lid interior

-

button latches hold the lid interior inside of the lid - see arrows

-

-

-

Lid interior was held together using aluminium pop rivets - had to remove them by drilling the head off and using a punch to knock the rivets out.

-

Stamped aluminium plate

-

Outer neoprene gasket - injection moulded

-

Inner neoprene gasket - injection moulded

-

Main body housing - ABS plastic injection moulded

-

Steel springs

-

Riveting surface? ABS plastic injection moulded

-

Latches - ABS plastic injection moulded

-

-

-

To remove the ABS plastic clips I had to use a nail/thin screwdriver to push the clip ends inside the housing

-

Aluminium plate (like other parts of this cooker) held on by crimped tabs - had to uncrimp them using a thin screwdriver

-

-

-

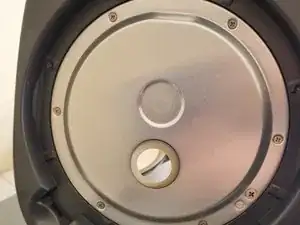

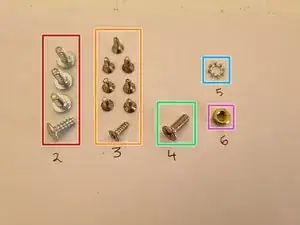

Inside the lid there was a secondary stamped aluminium Pannel. It was held onto the lid curiously by 13 individual Phillips head screws

-

12mm m3 Phillips head screw - stainless steel

-

9mm m2 Phillips head screw - stainless steel

-

12mm m3 Phillips head screw - nickel plated steel

-

Why 3 different types of screw with two different types of material used?

-

Brass nut for m3 screw/bolt

-

m3 washer for electronic component?

-

-

-

Once the interior aluminium plate was removed, there was a thin layer of aluminium foil held on using a thermal resistant adhesive. I pulled the foil off revealing a heat sensor

-

Heat sensor

-

Adhesive

-

Fuse?

-

-

-

Lid was connected by wires/leads that were adhered to the inside of the lid. Had to cut the wires with a wire cutter to be able to remove the lid.

-

Length: 270mm

-

Width: 232mm

-

height/Depth: 45mm

-

-

-

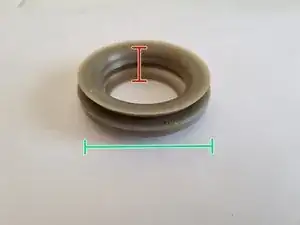

Inside the lid was a neoprene gasket - see purple for indication of where it went

-

Diameter of gasket:50mm

-

Hehgiht:15mm

-

-

-

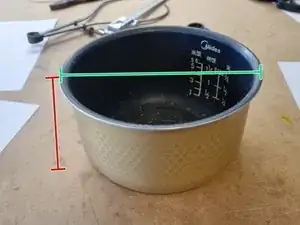

Spin moulded anodised aluminium bowl

-

PTFE nonstick coating on the inside

-

Height: 110mm

-

Diameter: 206mm

-