Introduction

The Turntable made weird mechanical sounds and lost drive force. It seems to have problems with the Motor (Direct-Drive).

The disassembling showed a loosen electromagnetic coil. After fixing this the turntable was working perfect again.

Before you start:

- Unplug all cables - Otherwise risk of death by electrical shock

- Know (at least a little) what you are doing

Tools

-

-

First of all you have to remove the needle, slipmate and the plate. Remove the turntable plate by lifting it up. It rests on a cone at the center axis. It will get loose with a *plopp*.

-

-

-

Pull up the small cover plate for the "remote control start/stop" plug allocated at the backside. It is fixed with double-sided adhesive tape

-

For turning around the turntable put maybe two books beside the main axis . So that the device is not resting at the main axis either then the tone arm!

-

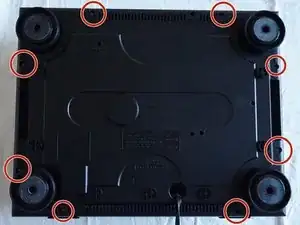

Loosen 8 screws with a Phillips screwdriver at the bottum of the turntabel. (signed red in picture).

-

Be aware that under every screw a spacing ring is allocated, the will fall away while opening the housing. (It is not a big problem during reassembling later)

-

-

-

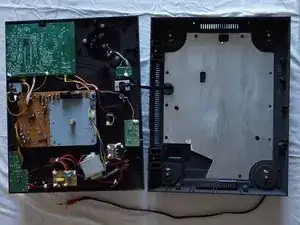

1st impression: looks cheap

-

blue: Audio cabeling from tone-arm to cinch cable.

-

green: light an switch

-

yellow: Start/Stop and speed setting pcb.

-

red: The direct-drive on a pcb under a metal housing.

-

-

-

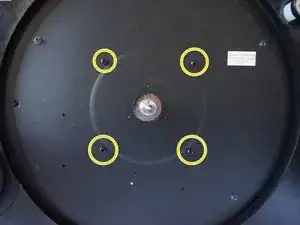

Tilt the housing for loosen the 4 phillips screws at the top (marked yellow).

-

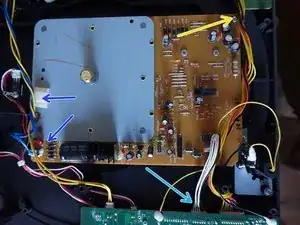

unplug the blue cable

-

unplug the white cable

-

unwrap the yellow cable-pack

-

loosen the last phillips screw holding the drive-pcb.

-

-

-

After removing the last srcew you can lift and turn the PCB. The Drive Axis (Pin) with its housing is held to the PCB by megnetic force. You can lift it up.

-

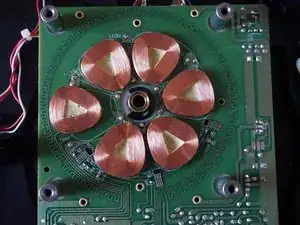

Here i found my problem; One of the 6 coils was loose and the cable was broken from the soldering. I checked the coil with a multimeter (continuity check - beep). The coil was despite some scratches still good and with the signs on the pcb i was able to solder the coil-cable back in place.

-

For the attachment of the coil to the pcb i choose a strong but still a little flexible glue ("UHU Kraft Alleskleber").

-

To reassemble your device, follow these instructions in reverse order.

3 comments

Hi friend,

I purchased an RP 8000 mk2 turntable from USA and had it shipped to Australia. The USA unit is 115 volts but I put 240 volts through it and now it won’t power up. I have since brought a step down power supply to use if I can repair the unit.

I was told in a forum that another guy done the same thing and all he did was get the 115 volt power supply replaced. After replacement he said the unit worked fine. I can’t confirm this.

Would putting 240 volts through my unit damage anything else? or would it be just as simple as replacing the power supply and it will work again as the other gentleman claimed?

Regards,

Turi

turi.wiki@gmail.com

Hallo,

Ik heb een tweedehands Reloop RP4000 MK2 draaitafel gekocht die niet regelmatig draaide, hij vertraagt lichtjes bij elke omwenteling. Ik dacht dat het om het probleem ging dat hier werd beschreven, dus ik heb uw instructies gevolgd.

Ik heb hem opengemaakt in de veronderstelling dat ik een losgesoldeerde spoel zou ontdekken, maar dat was niet het geval. Ik merkte echter dat er wrijving was bij de as, maar ik heb niet kunnen achterhalen hoe ik dit probleem kon oplossen. Ik heb alles weer in elkaar gezet, en sindsdien is de vertraging bij elke omwenteling nog sterker geworden.

Denkt u dat ik de as heb kunnen verbuigen bij het verwijderen en dat dit de oorzaak is van de toegenomen wrijving? Ik zoek hulp, maar waar kan ik die vinden?

Hello,

I have a second-hand Reloop RP4000 MK2 turntable that wasn’t spinning consistently; it slightly slows down with each rotation. I thought it might be the problem described here, so I followed your instructions.

I opened it up, expecting to find a desoldered coil, but that wasn’t the case. However, I did notice some friction at the spindle, but I couldn’t figure out how to fix this issue. I put everything back together, and since then, the slowdown with each rotation has become even more pronounced.

Do you think I might have bent the spindle when removing it, and that this is why the friction has increased? I’m looking for help, but I’m not sure where to find it.