Introduction

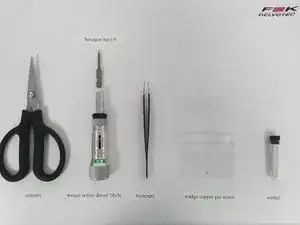

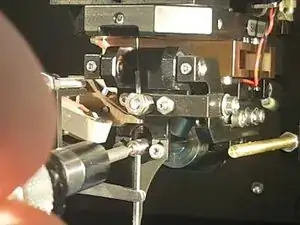

Tools

-

-

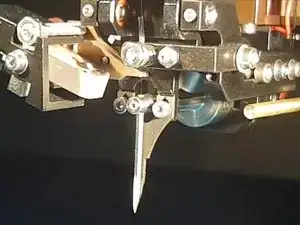

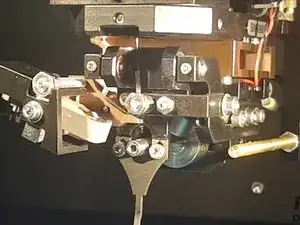

Put the wedge in the tranducer from below.

-

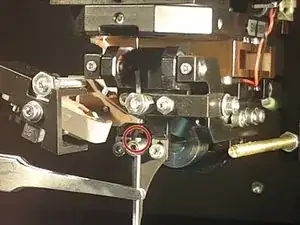

Correct Placement. Tool is flush with transducer.

-

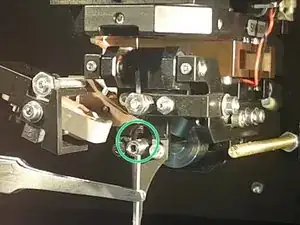

Incorrect Placement. tool is too high.

-

-

-

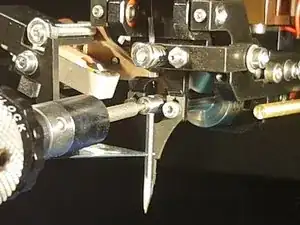

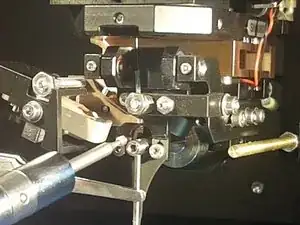

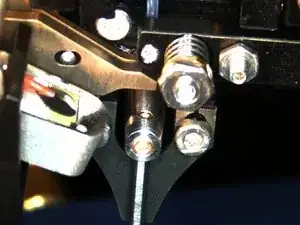

Fasten the screw lightly

-

Tighten the screw just so the wedge does not slip out of the tranducer.

-

-

-

Place gauge below Tool

-

Loosen the screw so the wedge slides onto the gauge Lever.

-

Lift the gauge up until in contact with the transducer horn.

-

Now the Tool-Top should be flush with the Transducer-Horn

-

Tighten the screw with the torque- wrench

-

-

-

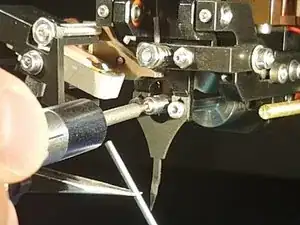

Use tweezers to push the wire down the wire hole, until it Ends some cm below the tool wedge.

-

Use scissors to cut the (contaminated) Wire down to a length of about 1cm below wedge end.

-

-

-

Use tweezers to thread the wire through the hole at the end of the wedge.

-

Afet threading pull the wire some cm through the hole.

-

To reassemble your device, follow these instructions in reverse order.