Introduction

Learning to fly an RC plane takes practice, inevitably experiencing minor crashes and damaging parts. Replaceable parts for RC planes are expensive or are not available for purchase. We will show you how to fix the Horizon Hobby Mini Apprentice S RC Plane Motor Mount by using a 3D printed model.

This guide requires a certain part to be 3D printed (resources will be mentioned later in the guide).

Also, a Phillips PH000 sized screwdriver (Phillips #000) comes with the plane itself but can be purchased if lost.

Please read the entire guide prior to attempting the repair.

Tools

-

-

While holding the propeller in place with your other hand, unscrew the single Phillips screw securing the front nose tip.

-

-

-

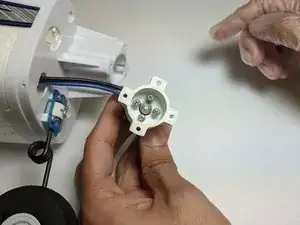

While holding the propeller in place, remove the front propeller assembly from the motor by loosening the hex nut.

-

-

-

3D print the replacement motor mount. Ifixit does not allow .stl or .3mf files to be imported, so Google Drive links to the files are given below.

-

If you do not have a 3D printer, try your local library or high school. Otherwise, google any of these: Protolabs, Shapeways, PCBWay, JLCPCB, or just google “3d printing service” (these cost money). When prompted, ask them to use PLA filament on an FDM 3D printer.

-

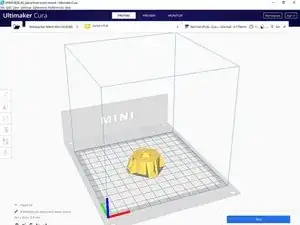

If you own a 3D printer: convert the .stl file into a .gcode file by using a slicer software such as Cura. If needed, look up Youtube videos on how to use your specific 3D printer. If needed, rotate the object along its z-axis in the slicer software until it matches the orientation in the image relative to the x, y, and z axes (very important).

-

If needed, resize it so the x, y, and z dimensions of the part are 39x39x15mm. In the image the x, y, z axes are red, green, and blue respectively. Also, the .3mf file is posted in case anyone wants to edit it in Fusion 360 (shouldn't be necessary).

-

-

-