Introduction

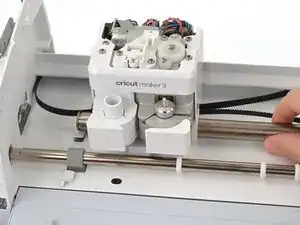

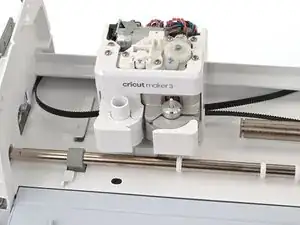

Follow this guide to replace the belt in your Cricut Maker 3.

If the tool holder in your Cricut Maker 3 is moving slowly, unreliably, or not at all, you may need to replace the belt.

Tools

Parts

-

-

Flip the Cricut over so the bottom is facing up.

-

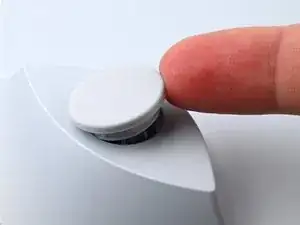

Use your finger to pry up and remove all four rubber feet from the bottom of the Cricut.

-

-

-

Use a Phillips screwdriver to remove the four 41 mm‑long screws securing the top cover to the base. There's one screw under each foot.

-

-

-

Flip the Cricut over so the silver lid is facing up.

-

Open the Cricut by lifting the top silver lid. The front tray will also open.

-

-

-

Insert the flat end of a spudger between the right side of the lid hinge cover and the top cover.

-

Use the spudger to pry up the cover.

-

-

-

Use the flat end of a spudger to pry up along the long edge of the lid hinge cover until the cover is free.

-

-

-

Use a Torx T8 screwdriver to remove the four 10.2 mm‑long screws securing the lid to the hinge.

-

-

-

Rotate the top cover to the right and prop it up so the right side of the cover is resting on your work surface.

-

-

-

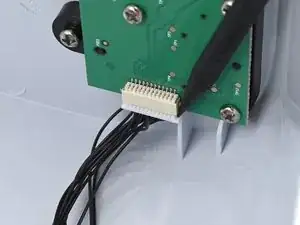

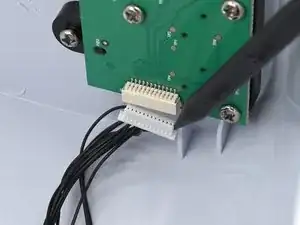

Use a spudger to disconnect the sliding connector from the button board by pushing on one side, then the other, until it's free.

-

-

-

Use a Phillips screwdriver to release the tension in the right hinge by pressing the inner portion of the hinge until it releases, then allowing it to turn clockwise until it comes to rest.

-

-

-

Use a Phillips screwdriver to release the tension in the left hinge by pressing the inner portion of the hinge until it releases, then allowing it to turn counterclockwise until it comes to rest.

-

-

-

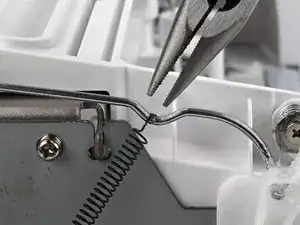

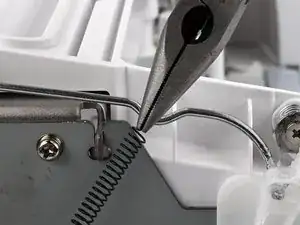

Use a pair of needle nose pliers or your fingers to lift the spring off of the tray release arm on the left end of the Cricut.

-

-

-

Remove the front end of the tray release arm from the front tray release mechanism by pulling it towards the center of the Cricut, then lifting it up.

-

If a lot of damping grease was lost during disassembly, use a spudger or popsicle stick to apply new high viscosity damping grease to the tray release mechanism.

-

Use paper towels and isopropyl alcohol to clean up any excess grease. If you're cleaning grease from electronic components, make sure you use high concentration (greater than 90%) alcohol.

-

-

-

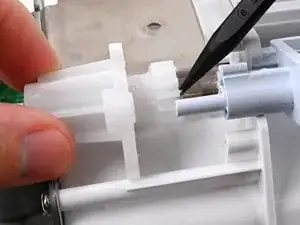

While pulling the left hinge with one hand, use a spudger to push the inner gear off of its post and remove the hinge.

-

-

-

Use a Phillips screwdriver to remove the three 10.0 mm‑long screws securing the right hinge.

-

-

-

While pulling the right hinge with one hand, use a spudger to push the inner gear off of its post and remove the hinge.

-

-

-

Pull the inner portion of the hinge out of the housing.

-

Use a spudger or popsicle stick to apply a small amount of high viscosity damping grease to the inner portion of the hinge.

-

Push the inner portion of the hinge back into the housing.

-

Scrape off excess grease with a spudger or popsicle stick. Use paper towels and isopropyl alcohol to clean grease off of any other surfaces. If you're cleaning grease from electronic components, make sure you use high concentration (greater than 90%) alcohol.

-

-

-

Free the back cover from the clips on the left and right sides by firmly pulling the cover away from the Cricut.

-

-

-

The plastic brackets on either side of the back cover have tabs that keep the bracket from coming out. Use one hand to pull back one of these tabs so the back cover can come off.

-

Remove the back cover by rotating the bottom edge up and pulling it away from the Cricut while holding the bracket out of the way.

-

-

-

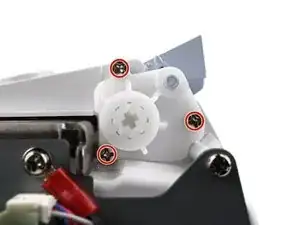

Use a Phillips screwdriver to remove the two 10.2 mm‑long screws securing the left end of the top metal track.

-

-

-

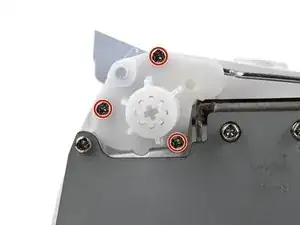

Use a Phillips screwdriver to remove eight screws from the right side of the Cricut:

-

Two 10.2 mm‑long screws securing the right end top metal track, which include a washer and a locking washer.

-

Four 10.0 mm‑long screws securing the large white plastic bracket.

-

Two 7.9 mm‑long screws securing the large white plastic bracket, which include white plastic spacers.

-

Check that the tool holder slides freely with the top metal track fully seated before re-installing any screws. If it doesn't, you may need to tilt the top of the tool holder forwards slightly so it's completely in the top track.

-

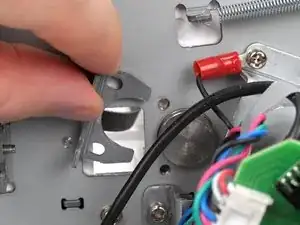

Reconnect the motor ground wire to the right-most screw that secures the right end of the top metal track.

-

-

-

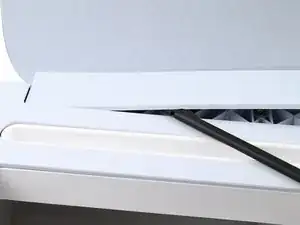

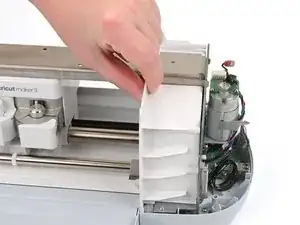

Lift the top metal track and slide it to the right to remove it, along with the large white plastic bracket.

-

-

-

Use a Phillips screwdriver to remove the 18.5 mm‑long tensioning screw from the bracket towards the back of the left side of the Cricut

-

Screw the nut away from the head of the screw by a few full turns.

-

Screw the screw into the hole in the bracket until the nut makes contact with the bracket.

-

Use a 6 mm wrench to hold the nut and screw in the screw until the belt reaches the correct tension.

-

-

-

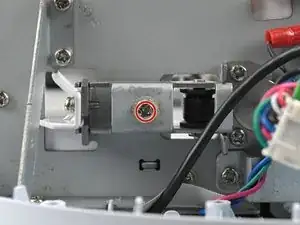

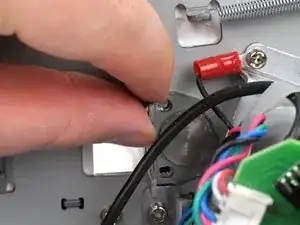

Use a spudger to walk the cable out of the sliding connector on top of the motor on the right side of the Cricut by pushing on one side, then the other, until it's free.

-

-

-

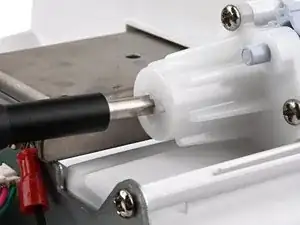

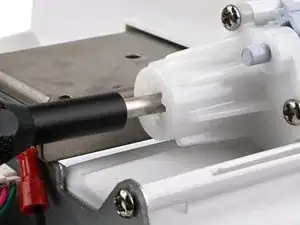

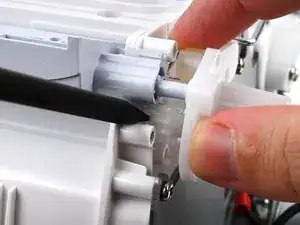

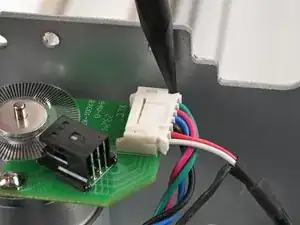

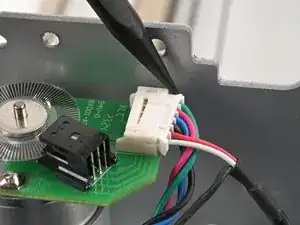

Rotate the motor counterclockwise one quarter turn to expose the E‑clip under the gear.

-

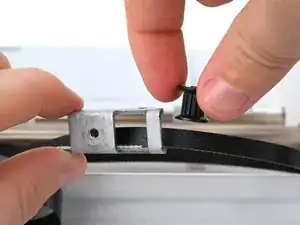

Use a small flathead screwdriver or other rigid prying tool to remove the E‑clip from the bottom of the right motor bracket.

-

-

-

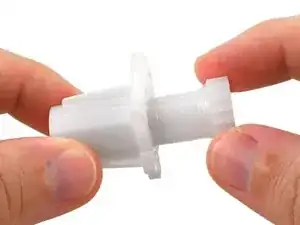

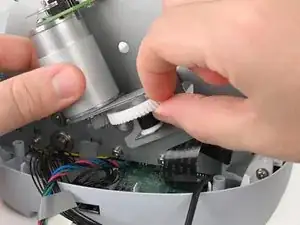

With one hand holding the motor, use your other hand to remove the gear from the motor bracket.

-

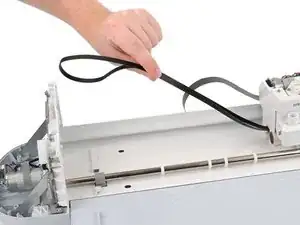

As the gear comes free of the bracket, lift the gear out of the belt.

-

Thread the belt through the opening in the motor bracket.

-

Insert the smaller part of the gear into the belt and replace the cap on the bottom of the gear.

-

Hold the gear, belt, and cap in place as you place the gear into the motor bracket.

-

-

-

Pull the bracket on the left side of the Cricut away from the frame until the bracket comes free.

-

-

-

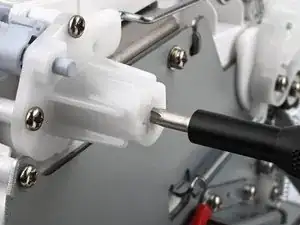

Use a small flathead screwdriver or other rigid prying tool to remove the E‑clip from the bottom of the left bracket assembly.

-

-

-

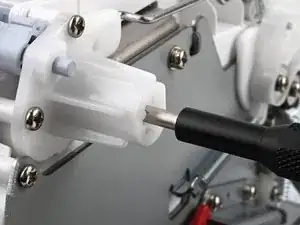

Lift the pin securing the gear out of the left bracket assembly bracket.

-

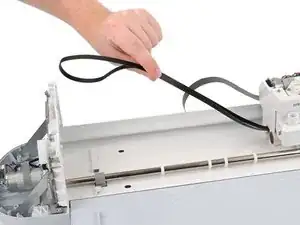

Remove the gear, allowing the belt to fall out of the bracket.

-

-

-

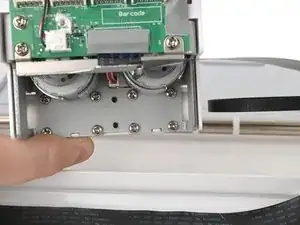

Use a Phillips screwdriver to remove the two 7.4 mm‑long screws securing the left tool holder bar bracket.

-

-

-

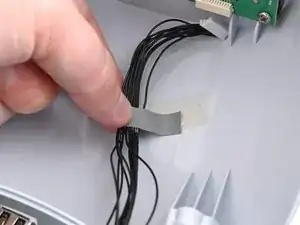

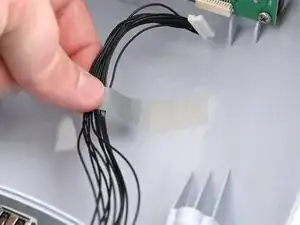

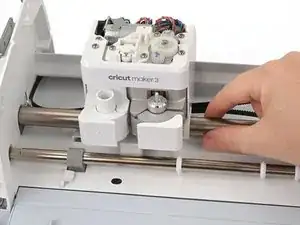

Pull the tool holder bar to the right, completely through the tool holder.

-

The tool holder bar may get stuck as it goes through the tool holder. Gently adjust the tool holder and bar until the bar easily slides through the tool holder.

-

If the tool holder bar does not align with the opening in the frame after going through the tool holder, lift the tool holder off of the rear track and re-seat it so the bar aligns with the opening.

-

-

-

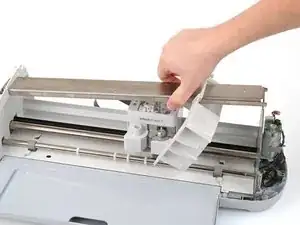

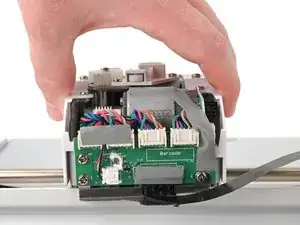

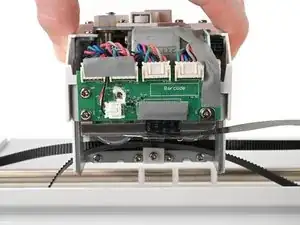

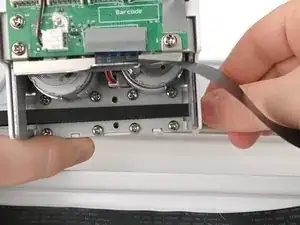

Lift the tool holder off the bottom track until you can access the screws on the bottom of the tool holder.

-

-

-

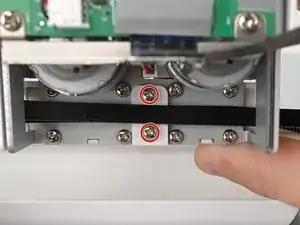

Use a Phillips screwdriver to remove the two 9.8 mm‑long screws securing the belt to the tool holder.

-

To reassemble your device, follow these instructions in reverse order.

Repair didn’t go as planned? Try some basic troubleshooting, or ask our Answers community for help.