Introduction

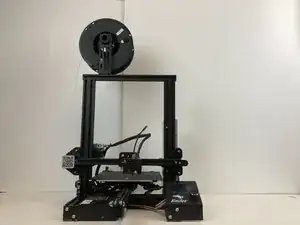

The hot end of a 3D printer is the most common cause for failed prints and general problems with a printer. This is due to the nature of the hotend, as it is the most used and strained part of a printer. Replacing the hotend is, fortunately, not too difficult. This guide details how to replace the hotend of an Ender 3 3D printer. As a warning, this process may involve working with a heated element that is around 240 degrees Celsius or 464 degrees Fahrenheit, extreme caution is advised.

Tools

Parts

-

-

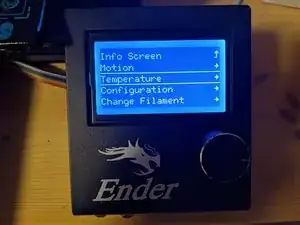

Press the knob to enter the marlin LCD menu and turn it to navigate between the options.

-

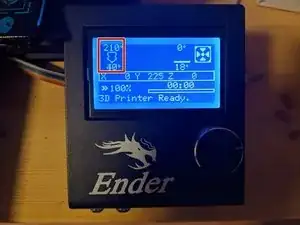

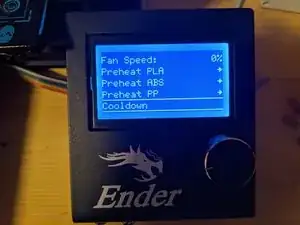

Navigate to Temperature > Nozzle.

-

Adjust the nozzle temperature by turning the knob and confirm by pressing it.

-

-

-

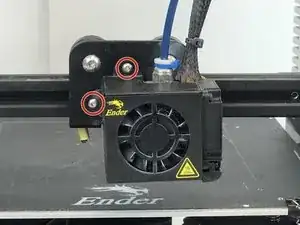

Remove the two screws from the fan housing using the 2 mm hex key.

-

Pull the housing away from the hotend assembly and set the screws aside.

-

-

-

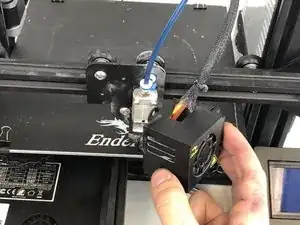

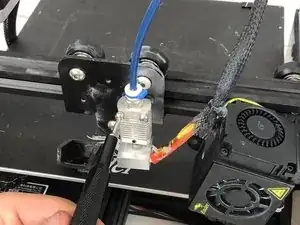

Remove the Bowden tube from the hotend or the extruder assembly.

-

Remove the blue plastic clip from the push fitting.

-

Push down on the grey part of the push fitting and simultaneously pull on the bowden tube.

-

-

-

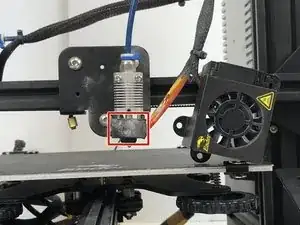

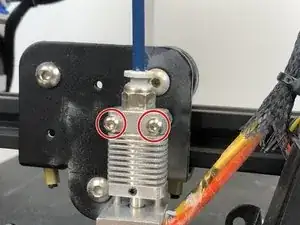

Remove the two large screws from the heatsink of the hotend using the 2mm hex key.

-

Pull the hotend away from the gantry.

-

-

-

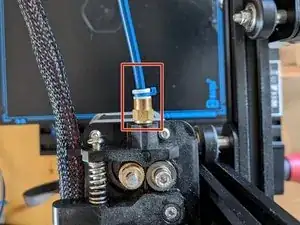

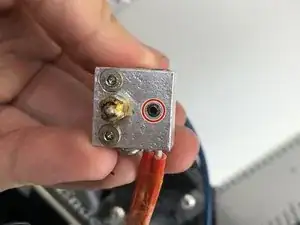

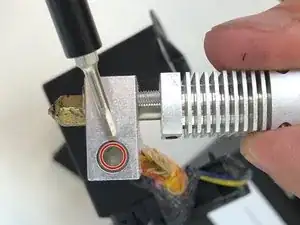

Remove the grub screw from the base of the hotend with the 1.5mm hex key.

-

Set the grub screw aside.

-

-

-

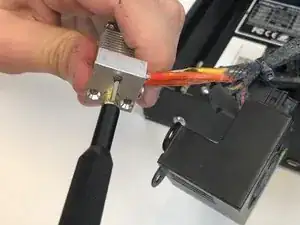

Lightly push against the heater cartridge using a hex key to remove it from the hotend.

-

Remove the Phillips head screw to remove the thermistor, being very careful not to sever the thermistor wire.

-

To reassemble your device, follow these instructions in reverse order. Make sure that if you kept the original tubing, that the tubing inserted into the hotend is pushed all the way down.

One comment

I needed the wiring diagram. My replacement comes with the preassembled hotend.

Auda -