Introduction

Issue: sewing machine bogs down every 8-15 stitches.

Replace the broken/worn out gear on the stitch cam shaft.

Tools

Parts

-

-

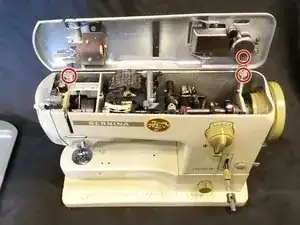

Open the top of the machine to expose the internal mechanism.

-

It is easier to replace the gear without the top cover in place. Loosen the screw holding the cover arm on. Remove the pin and set aside for later.

-

Remove the two screws holding the hinges. Set the cover aside.

-

-

-

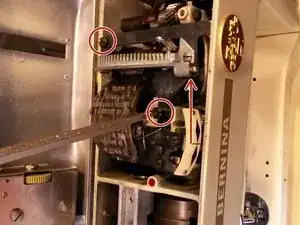

Remove the three screws holding the assembly down. In my case one of the screws was stuck and I had to use locking pliers to loosen it.

-

Push the needle position indicator to the side to access the screw beneath it.

-

Pull the assembly to the left and up. It should come out easily.

-

-

-

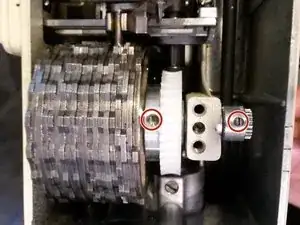

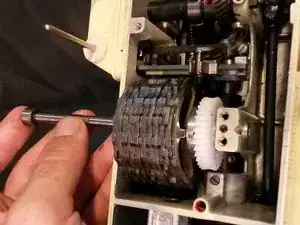

The shaft is held in by the set screws on the gear hubs: 1 on the cam gear, 2 on the little pinion gear 90 degrees apart. Loosen them 3 turns or so with a jewelers screwdriver.

-

Slide the pinion gear to the end of the shaft. Gently slide the shaft back with needle nose pliers. Catch the gear before it falls.

-

Push the shaft out the back then finish pulling it out.

-

-

-

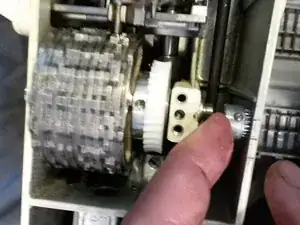

Loosen the two screws holding the gear and cam assembly together so that the screws can come out. Keep the screws in the holes to keep everything together.

-

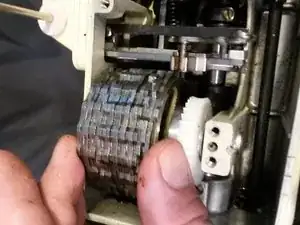

Push the gear shaft with fingers or screwdriver to slide it out. It may require the use of two screwdrivers to pry out.

-

-

-

Insert the new gear shaft into the cam assembly. Line up the holes and thread the screws in.

-

The new gear I bought came with an Allen head set screw so I swapped the old flat head setscrew into the new shaft.

-

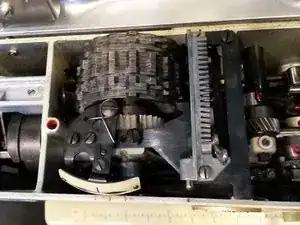

Set the gear and cam assembly in the sewing machine.

-

-

-

Slide the shaft in, small end first, until it just protrudes from bearing on the gear side.

-

Hold the pinion gear in place and slide the shaft the remainder of the way into it.

-

Tighten the set screws on the gears (there are 2 on the pinion).

-

-

-

Slide the needle indicator in from the left. Push the stitch selector aside as needed.

-

Install the three screws in reverse order that you removed them.

-

Turn the machine manually at least one full turn to make sure everything is properly in it's place.

5 comments

I need to replace the timing belt inside my Morse FA-630 machine. I'm still hunting down parts for this ancient machine, but I'm going to fix it myself. Do you have any pointers or concerns I need to be aware of?

Do you do repairs?

Do you do repairs? I have a Bernina 1230 I was told was toast but feel it is worth refurbishing

No, I'm just a mechanic that likes fixing things. If the dedicated repair shop says it's toast then I'd go with their opinion.